Biomedicine

The use of CAE systems for biomedical tasks requires tools that can work with complex surfaces, small areas and details, as well as carry out multidisciplinary analysis. Altair HyperWorks has best-in-class solutions that allow you to create KE grids, optimize structures and structures, and analyze the results obtained. HyperWorks tools make it possible to quickly and effectively evaluate the design, quality and durability of the designed structures, as well as competently simulate the processes characteristic of various medical fields.

Altair HyperWorks in Orthopedics, Biomechanics and Medical equipment design

International healthcare is a dynamically developing industry characterized by an increase in the cost of medical services and insurance, as well as an increase in the needs of the population. Also, healthcare is an industry of creating and improving medical technologies and tools. Developers and manufacturers of medical equipment are trying to improve the characteristics of the designed products, to ensure quality and reliability, while their developments must meet the established standards. Every year, biomedical equipment development companies are increasingly using CAE modeling to effectively design and solve product quality problems. The design using computer engineering methods has been approved by the American Commission in the Field of Supervision of Medicines and Food and other management bodies.

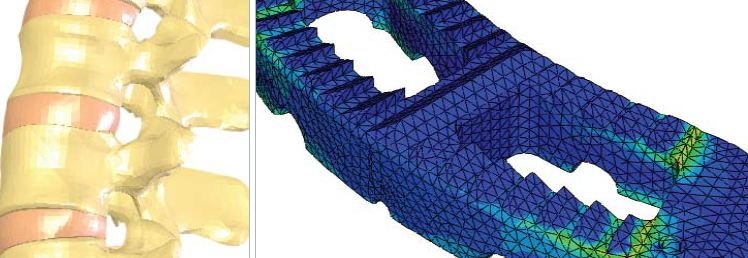

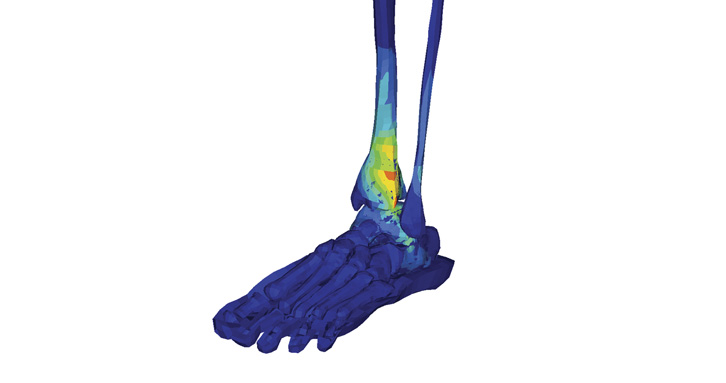

Assessment of the distribution of loads in the bone

Altair HyperWorks has a comprehensive set of tools for CAE modeling that allow you to solve the most complex tasks in biomedicine, for example:

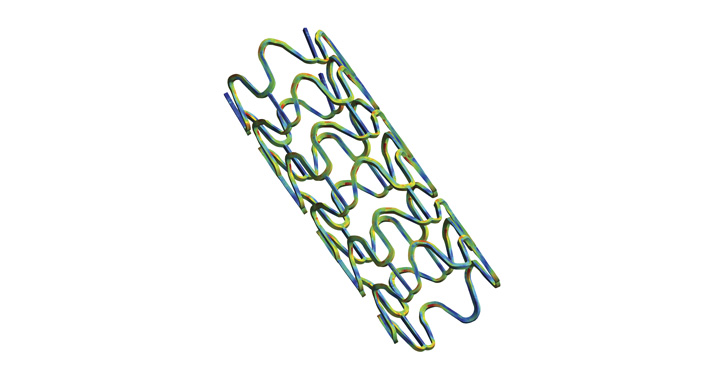

- Complex nonlinear phenomena such as stenting, tissue modeling and aortic valve stenosis

- Creation of innovative competitive medical devices that will help make various healthcare industries more modern and cost-effective

- Fulfillment of engineering and medical requirements for new equipment, ensuring high quality of devices and their durability

The HyperWorks platform, which allows optimizing the design of structures and devices, competently and efficiently managing data and automating production processes, is the best solution for companies engaged in various areas in the biomedical industry.

- Complex nonlinear phenomena such as stenting, tissue modeling and aortic valve stenosis

- Creation of innovative competitive medical devices that will help make various healthcare industries more modern and cost-effective

- Fulfillment of engineering and medical requirements for new equipment, ensuring high quality of devices and their durability

The HyperWorks platform, which allows optimizing the design of structures and devices, competently and efficiently managing data and automating production processes, is the best solution for companies engaged in various areas in the biomedical industry.

Stent analysis

High-precision modeling with Altair

The HyperWorks platform allows high-precision modeling of complex structures and conducting research in biomedical engineering.

- Using the HyperMesh software system for quick and easy correction of already existing grids (such as STL models) even without “binding” to geometry (IGES format)

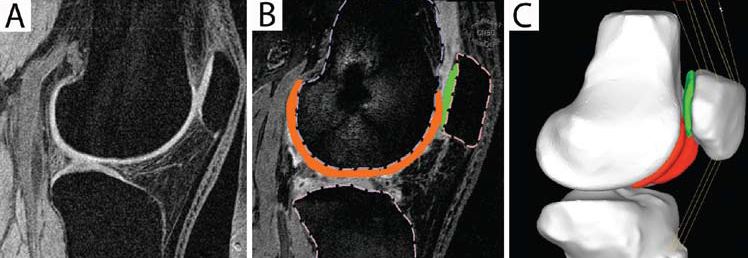

- Processing of small-sized areas of human joints and bones and creating a high-quality CE model

- Modeling of complex nonlinear phenomena, such as aortic valve stenosis, using software systems for analyzing the flow of liquids and gases RADIOSS and AcuSolve

- Modeling of physico-biological processes, such as blood flow in the treatment of aneurysms, using HyperMesh, AcuSolve, as well as other partner CFD solvers

- Modeling and forecasting of the mechanisms of bodily injuries, such as bruises, cuts, fractures, etc. using RADIOSS

- Using the HyperMesh software system for quick and easy correction of already existing grids (such as STL models) even without “binding” to geometry (IGES format)

- Processing of small-sized areas of human joints and bones and creating a high-quality CE model

- Modeling of complex nonlinear phenomena, such as aortic valve stenosis, using software systems for analyzing the flow of liquids and gases RADIOSS and AcuSolve

- Modeling of physico-biological processes, such as blood flow in the treatment of aneurysms, using HyperMesh, AcuSolve, as well as other partner CFD solvers

- Modeling and forecasting of the mechanisms of bodily injuries, such as bruises, cuts, fractures, etc. using RADIOSS

High-precision modeling with Altair

The HyperWorks platform allows high-precision modeling of complex structures and conducting research in biomedical engineering.

- Using the HyperMesh software system for quick and easy correction of already existing grids (such as STL models) even without “binding” to geometry (IGES format)

- Processing of small-sized areas of human joints and bones and creating a high-quality CE model

- Modeling of complex nonlinear phenomena, such as aortic valve stenosis, using software systems for analyzing the flow of liquids and gases RADIOSS and AcuSolve

- Modeling of physico-biological processes, such as blood flow in the treatment of aneurysms, using HyperMesh, AcuSolve, as well as other partner CFD solvers

- Modeling and forecasting of the mechanisms of bodily injuries, such as bruises, cuts, fractures, etc. using RADIOSS

- Using the HyperMesh software system for quick and easy correction of already existing grids (such as STL models) even without “binding” to geometry (IGES format)

- Processing of small-sized areas of human joints and bones and creating a high-quality CE model

- Modeling of complex nonlinear phenomena, such as aortic valve stenosis, using software systems for analyzing the flow of liquids and gases RADIOSS and AcuSolve

- Modeling of physico-biological processes, such as blood flow in the treatment of aneurysms, using HyperMesh, AcuSolve, as well as other partner CFD solvers

- Modeling and forecasting of the mechanisms of bodily injuries, such as bruises, cuts, fractures, etc. using RADIOSS

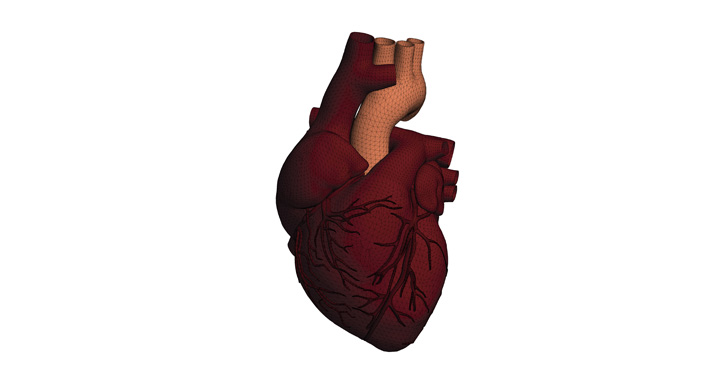

A heart model built in HyperMesh

Innovative design

Altair's advanced manufacturing technologies allow you to create and optimize the design of any structure in the shortest possible time

- From the geometry constructed in HyperMesh, you can create a number of its various variations using the HyperMorph tool, designed to change the KE model with minimal deformation of the constructed mesh

- The HyperView software system makes it possible to conduct a quick visual assessment and comparative analysis of structures

- Using the HyperStudy system, structures can be parametrically optimized to achieve the desired efficiency of the device and the distribution of material within the structure

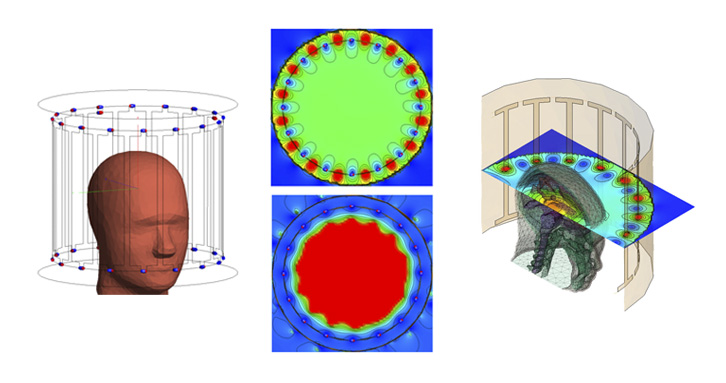

- The analysis of the problems of electromagnetism plays one of the key roles in designing efficient structures and achieving a high level of safety in biomedicine. This analysis is especially important when solving wireless telemetry problems, such as wireless medical sensors, implantable devices (pacemakers, neurostimulators), MRI systems. The advanced FEKO CE system allows you to solve all these tasks in the most effective way.

- From the geometry constructed in HyperMesh, you can create a number of its various variations using the HyperMorph tool, designed to change the KE model with minimal deformation of the constructed mesh

- The HyperView software system makes it possible to conduct a quick visual assessment and comparative analysis of structures

- Using the HyperStudy system, structures can be parametrically optimized to achieve the desired efficiency of the device and the distribution of material within the structure

- The analysis of the problems of electromagnetism plays one of the key roles in designing efficient structures and achieving a high level of safety in biomedicine. This analysis is especially important when solving wireless telemetry problems, such as wireless medical sensors, implantable devices (pacemakers, neurostimulators), MRI systems. The advanced FEKO CE system allows you to solve all these tasks in the most effective way.

MRI simulation using the FEKO electromagnetic problem solver

Automatic quality control

Thanks to the HyperWorks platform and Altair partner solutions, it is possible to check the quality and reliability of medical devices.

- The ability to assemble one or more CAD files to build a C-grid using HyperWorks or another software grid builder

- Identification of several design options in order to optimize them using HyperStudy

- Ensuring optimal durability of devices and structures, such as implants, using Altair partner solutions for fatigue assessment (link to partner alliance our website)

Using the capabilities of the Altair HyperWorks platform to automate processes, such as, for example, stenting, allows not only to standardize grid generation and load assignment, but also to manage important data automatically.

- The ability to assemble one or more CAD files to build a C-grid using HyperWorks or another software grid builder

- Identification of several design options in order to optimize them using HyperStudy

- Ensuring optimal durability of devices and structures, such as implants, using Altair partner solutions for fatigue assessment (link to partner alliance our website)

Using the capabilities of the Altair HyperWorks platform to automate processes, such as, for example, stenting, allows not only to standardize grid generation and load assignment, but also to manage important data automatically.