A software system for fast and accurate simulation of the flow of air around cars.

Virtual Wind Tunnel

HyperWorks Virtual Wind Tunnel is distinguished by the efficient use of several Altair technologies, including modern methods of creating a finite element grid and modeling fluid dynamics with high accuracy, and intuitive, automated and streamlined workflow and user interface. Thanks to these features, HyperWorks Virtual Wind Tunnel allows you to evaluate the external aerodynamic characteristics of the car to a new level of accuracy and speed.

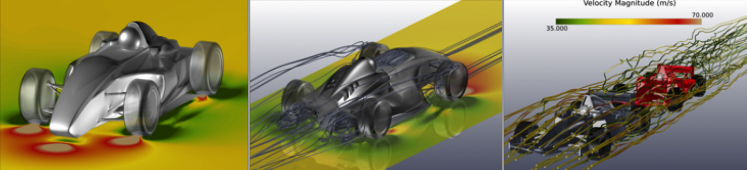

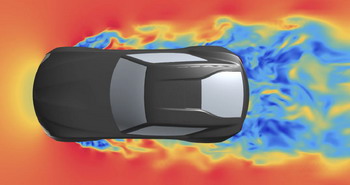

Modeling of the flow around the external flow plays an important role in the design of modern vehicles. Fuel consumption, vehicle stability, engine cooling, noise inside the car and the efficiency of the wipers – all this depends on the aerodynamic forces acting on the moving car. Modeling the flow in a wind tunnel using computational fluid dynamics (CFD) methods allows engineers to study aerodynamic loads. The use of these methods will also reduce the number of necessary field experiments in the process of developing a new vehicle.

Modeling of the flow around the external flow plays an important role in the design of modern vehicles. Fuel consumption, vehicle stability, engine cooling, noise inside the car and the efficiency of the wipers – all this depends on the aerodynamic forces acting on the moving car. Modeling the flow in a wind tunnel using computational fluid dynamics (CFD) methods allows engineers to study aerodynamic loads. The use of these methods will also reduce the number of necessary field experiments in the process of developing a new vehicle.

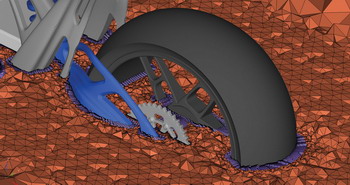

Finite element model for calculation in Virtual Wind Tunnel

Visualization of air flows flowing around the car and modeled in the Virtual Wind Tunnel system

The new software is based on AcuSolve, Altair's CFD solver, which was chosen for its speed, scalability, reliability and accuracy. AcuSolve's advanced turbulence modeling technologies allow HyperWorks Virtual Wind Tunnel to quickly and accurately predict the flow field and flow disruption for static and time-variable processes. AcuSolve's best-in-class fluid-solid interaction simulation solution makes more realistic and fully automatic wind tunnel simulation available.

Another advantage of HyperWorks Virtual Wind Tunnel is the use of modern methods of creating a mesh cache. The Virtual Wind Tunnel software system offers the user a fully automated tool for constructing a grid taking into account the boundary layer, which is the most important in aerodynamics. The creation of a volumetric mesh for the aerodynamic analysis of the car – including the external elements of the chassis, body kit and the creation of a boundary layer – can be completely completed in less than two hours. The CFD solver underlying HyperWorks Virtual Wind Tunnel is quite undemanding to the geometry of finite element elements, it provides an additional opportunity to work with elements close to degenerate, the generation of which is almost inevitable when working with complex geometry. The solver's flexibility eliminates the time-consuming stage of grid optimization, significantly reducing the time required for the calculator to create it.

Advantages of using Virtual Wind Tunnel

Creating a finite element grid:

* Ability to set the level of "fineness" of the grid

* Ability to define zones/volumes to automatically reduce the size of elements (refinement)

* User-accessible settings for building a border layer grid

* Construction of the boundary layer grid only in the required zones, which reduces the total number of elements in the model

* Progressive methods of constructing a boundary layer grid for working with complex geometry

Model Settings:

* The ability to set the rotation of wheels, radiator zones

* Option of setting a moving platform in a wind tunnel

* Automatic calculation of the midsection area

Solver:

* Availability of all the best solutions from AcuSolve

* Low demands on the quality of finite elements

* High scalability capabilities (similar to threads) even for CES grids with a relatively small number of nodes

* Turbulence modeling

Processing of analysis results:

* Automatic report generation, which includes a set of results for different calculation models, statistical data on the grid, drag coefficient, etc.

You can learn more about the capabilities of the Virtual Wind Tunnel software system by watching this video:

Another advantage of HyperWorks Virtual Wind Tunnel is the use of modern methods of creating a mesh cache. The Virtual Wind Tunnel software system offers the user a fully automated tool for constructing a grid taking into account the boundary layer, which is the most important in aerodynamics. The creation of a volumetric mesh for the aerodynamic analysis of the car – including the external elements of the chassis, body kit and the creation of a boundary layer – can be completely completed in less than two hours. The CFD solver underlying HyperWorks Virtual Wind Tunnel is quite undemanding to the geometry of finite element elements, it provides an additional opportunity to work with elements close to degenerate, the generation of which is almost inevitable when working with complex geometry. The solver's flexibility eliminates the time-consuming stage of grid optimization, significantly reducing the time required for the calculator to create it.

Advantages of using Virtual Wind Tunnel

Creating a finite element grid:

* Ability to set the level of "fineness" of the grid

* Ability to define zones/volumes to automatically reduce the size of elements (refinement)

* User-accessible settings for building a border layer grid

* Construction of the boundary layer grid only in the required zones, which reduces the total number of elements in the model

* Progressive methods of constructing a boundary layer grid for working with complex geometry

Model Settings:

* The ability to set the rotation of wheels, radiator zones

* Option of setting a moving platform in a wind tunnel

* Automatic calculation of the midsection area

Solver:

* Availability of all the best solutions from AcuSolve

* Low demands on the quality of finite elements

* High scalability capabilities (similar to threads) even for CES grids with a relatively small number of nodes

* Turbulence modeling

Processing of analysis results:

* Automatic report generation, which includes a set of results for different calculation models, statistical data on the grid, drag coefficient, etc.

You can learn more about the capabilities of the Virtual Wind Tunnel software system by watching this video: