A family of finite element solvers for RADIOSS structural analysis.

The RADIUS software system is used for QE modeling of structures, the flow of liquids and gases, the interaction of liquids and structures, metal stamping, dynamic behavior of mechanical systems (in particular, performing crash and drop tests). This multidisciplinary analysis tool allows manufacturers to maximize the wear resistance of the product, minimize noise and vibration, solve the problems of crash analysis, analyze the safety of vehicles, the manufacturability of the product design. RADIOSS is used in all industries around the world to increase the impact resistance, safety and manufacturability of the designed product.

Functions and features

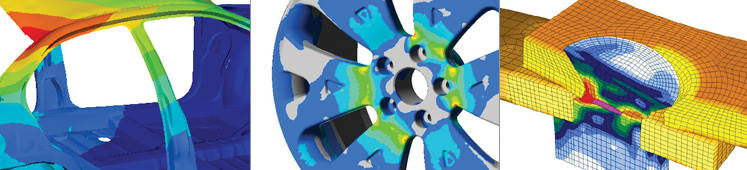

RADIOSS applications include passive safety analysis, drop tests and shock effects, explosions, hydrodynamic impacts, analysis of the interaction of liquids and solids, ballistics, modeling of ultra-high-speed shock phenomena, stamping, "mapping" of composites.

Functions and features

RADIOSS applications include passive safety analysis, drop tests and shock effects, explosions, hydrodynamic impacts, analysis of the interaction of liquids and solids, ballistics, modeling of ultra-high-speed shock phenomena, stamping, "mapping" of composites.

Scalability, sustainability and quality of solutions

RADIOSS advanced multiprocessor solutions have the best scalability for analyzing structural problems on large highly nonlinear models. The system features guarantee high adequacy of results regardless of the number of cores, nodes or threads used in parallel computing. The numerical spread of the calculation results is minimized. The use of Advanced Mass Scaling (AMS) and the single precision method increases the speed of calculations by orders of magnitude, while maintaining the degree of accuracy of the results. AMS provides a competitive solution for quasistatics and model analysis problems that require the use of local shredding of the CE grid. The multi-domain approach used in RADIOSS gives great advantages in the scrupulous analysis of the geometry of a part with a fine mesh inside a global assembly, as well as in modeling such complex phenomena as an emergency landing on water (the interaction of a deformable solid and liquid).

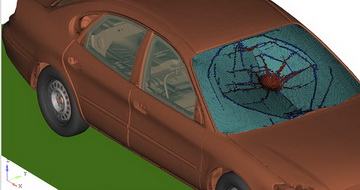

Applications of the XFEM method: modeling of car windshield damage

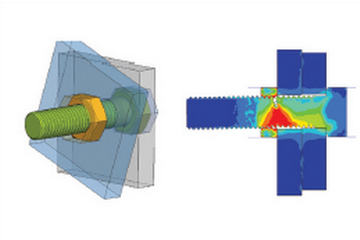

Modeling of a bolt taking into account the destruction of materials in RADIOSS

Industry Standard for crash test simulation, passenger safety and impact interaction analysis

For more than 30 years, RADIOSS has established itself as the leading industry standard for crash test simulation, passive safety analysis and impact interactions. The number of users of this system continues to increase at an impressive rate and currently has more than 1,000 companies around the world, of which 40% are enterprises of the automotive industry.

RADIOSS is rightfully considered the best-in-class crash test simulation software and is highly appreciated by companies from the automotive and aerospace industries as a tool for accurate analysis and evaluation of the behavior of complex mechanical systems in the simulation of collisions and impact phenomena. RADIOSS has direct access to an extensive library of CE models - dummies, barriers and strikers for calculating the passive safety of vehicles.

For more than 30 years, RADIOSS has established itself as the leading industry standard for crash test simulation, passive safety analysis and impact interactions. The number of users of this system continues to increase at an impressive rate and currently has more than 1,000 companies around the world, of which 40% are enterprises of the automotive industry.

RADIOSS is rightfully considered the best-in-class crash test simulation software and is highly appreciated by companies from the automotive and aerospace industries as a tool for accurate analysis and evaluation of the behavior of complex mechanical systems in the simulation of collisions and impact phenomena. RADIOSS has direct access to an extensive library of CE models - dummies, barriers and strikers for calculating the passive safety of vehicles.

Extensive library of physical and mechanical properties of materials, as well as destruction criteria

RADIOSS contains extensive libraries of physical and mechanical properties of materials and fracture criteria; more than 300 combinations are available. RADIOSS also includes an impressive variety of materials with linear and nonlinear properties, criteria for cracking and fracture, allowing you to explore complex processes. Multi-criteria fracture analysis can be applied to any material. Crack propagation in layered structures is effectively modeled using a specialized finite element method (XFEM). Using the Euler, Lagrange-Euler and SPH methods, RADIOSS allows you to simulate the interaction of liquids/gases and deformable solids, taking into account a large number of flows. The innovative finite volume method allows a multi-faceted FSI analysis of the behavior of car airbags to be carried out quickly and with a high degree of accuracy, thanks to the use of digital twins.

Models for optimization

Full integration with the HyperWorks platform makes RADIOSS an incredibly powerful software product, and the models created in the software system can be easily used for the optimization process. In order to improve the characteristics of the designed structure, engineers can perform design optimization and structural stability studies using, respectively, Altair OptiStruct and HyperStudy.

Highly parallel computing

In the modern world of advanced technologies, digital economy and market globalization, the speed of their execution comes out on top along with the quality of calculations. The RADIOSS family of solvers allows you to minimize the time of product development and its launch to the market due to the maximum efficiency of highly parallel computing. RADIOSS is the industry standard for the application of HPC solutions.

RADIOSS contains extensive libraries of physical and mechanical properties of materials and fracture criteria; more than 300 combinations are available. RADIOSS also includes an impressive variety of materials with linear and nonlinear properties, criteria for cracking and fracture, allowing you to explore complex processes. Multi-criteria fracture analysis can be applied to any material. Crack propagation in layered structures is effectively modeled using a specialized finite element method (XFEM). Using the Euler, Lagrange-Euler and SPH methods, RADIOSS allows you to simulate the interaction of liquids/gases and deformable solids, taking into account a large number of flows. The innovative finite volume method allows a multi-faceted FSI analysis of the behavior of car airbags to be carried out quickly and with a high degree of accuracy, thanks to the use of digital twins.

Models for optimization

Full integration with the HyperWorks platform makes RADIOSS an incredibly powerful software product, and the models created in the software system can be easily used for the optimization process. In order to improve the characteristics of the designed structure, engineers can perform design optimization and structural stability studies using, respectively, Altair OptiStruct and HyperStudy.

Highly parallel computing

In the modern world of advanced technologies, digital economy and market globalization, the speed of their execution comes out on top along with the quality of calculations. The RADIOSS family of solvers allows you to minimize the time of product development and its launch to the market due to the maximum efficiency of highly parallel computing. RADIOSS is the industry standard for the application of HPC solutions.

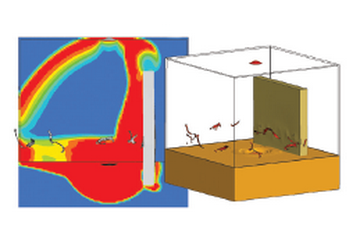

Applications of the FSI method: explosive impact on the assembly of a steel body and a concrete wall

Advantages of RADIOSS:

* Solver verified for nonlinear dynamic analysis by explicit method, implicit method, for solving problems of hydro-gas dynamics

* Built-in SPH method (Smooth Particle Hyrdodynamics)

* Submodule for modeling the metal stamping process

* Availability of a library of verified defining ratios and destruction criteria for materials

RADIOSS Features:

* Good scalability of large highly nonlinear computational models

* Extensive library of physical and mechanical properties of materials, as well as destruction criteria

* A unique tool for accurately modeling the behavior of airbags

* A large set of opportunities for multidisciplinary analysis

* A wide selection of built-in CE models: mannequins, barriers and strikers

Types of analysis:

You can find out about the capabilities of the RADIOSS family of solvers by watching this video:

* Solver verified for nonlinear dynamic analysis by explicit method, implicit method, for solving problems of hydro-gas dynamics

* Built-in SPH method (Smooth Particle Hyrdodynamics)

* Submodule for modeling the metal stamping process

* Availability of a library of verified defining ratios and destruction criteria for materials

RADIOSS Features:

* Good scalability of large highly nonlinear computational models

* Extensive library of physical and mechanical properties of materials, as well as destruction criteria

* A unique tool for accurately modeling the behavior of airbags

* A large set of opportunities for multidisciplinary analysis

* A wide selection of built-in CE models: mannequins, barriers and strikers

Types of analysis:

- Nonlinear explicit dynamics, implicit structural analysis

- Lagrange, Euler, ALE-method methods

- Finite volume method

You can find out about the capabilities of the RADIOSS family of solvers by watching this video: