Altair Inspire Form is a software for modeling sheet metal stamping, which gives users the opportunity to optimize their products for production with advance assessments of the characteristics of forming, the use of specific materials and cost. Express evaluation of technical implementation is possible thanks to the industry's best "one-step inverse" technology.

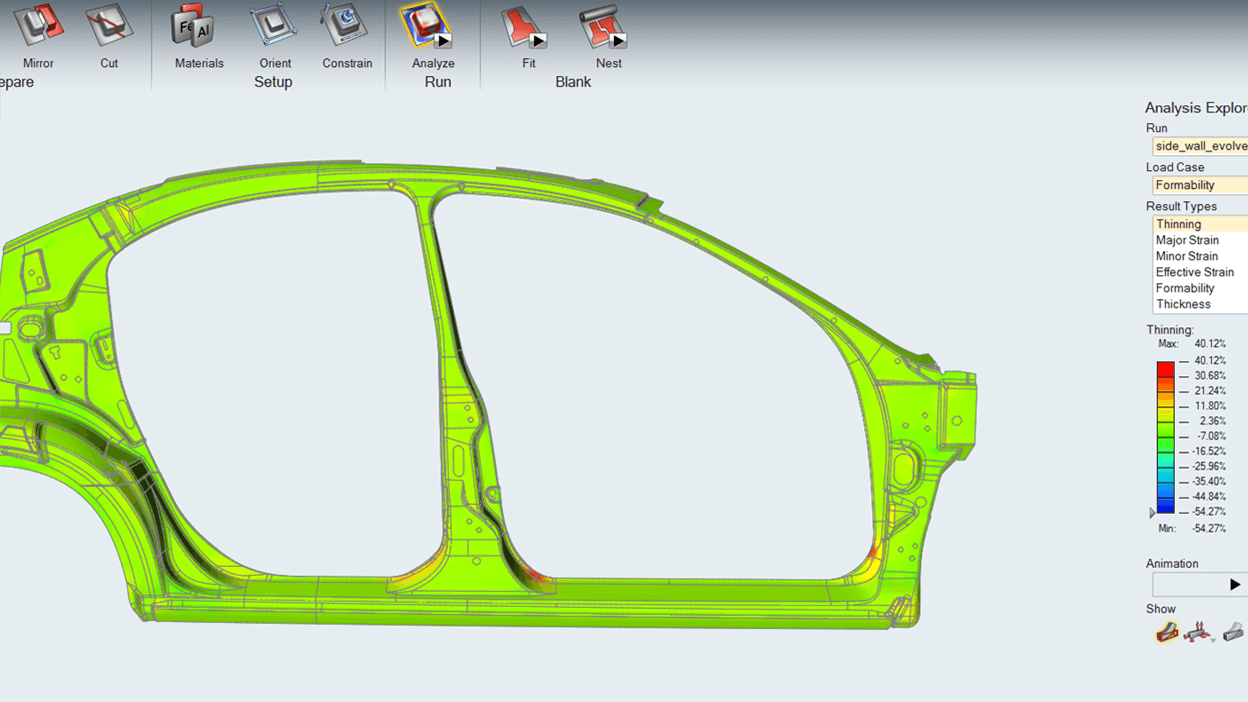

In addition to the designation of areas where the destruction of the part is possible due to the appearance of breaks and thinning of the product, Altair Inspire Form has functions for a comprehensive assessment of the quality of the workpiece, which ensures the optimal shape of the blank, including automatic layout of parts on a sheet of metal and the associated costs.

In addition to the designation of areas where the destruction of the part is possible due to the appearance of breaks and thinning of the product, Altair Inspire Form has functions for a comprehensive assessment of the quality of the workpiece, which ensures the optimal shape of the blank, including automatic layout of parts on a sheet of metal and the associated costs.

Main features of Altair Inspire Form:

Production of optimal products:

Production of optimal products:

- Fast and reliable assessment of the technological capability of stamping the structure;

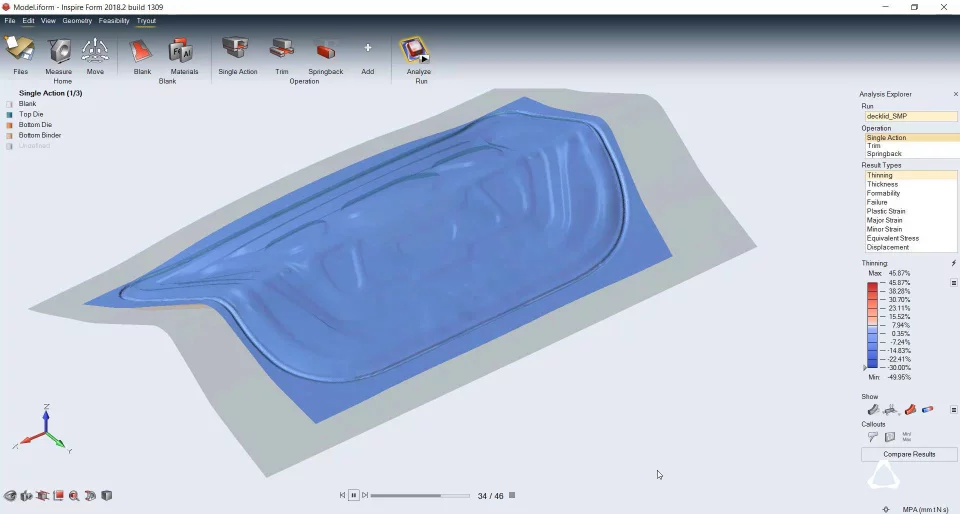

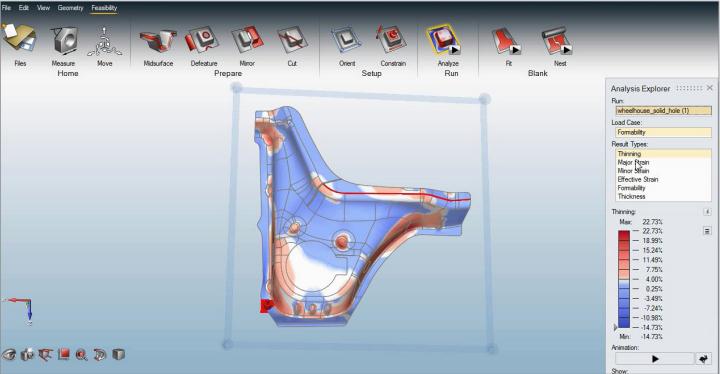

- Visualization of areas with potential defects (with gaps, weights and areas with non-rigid joints);

- Modification of the design, template (thickness), type of material used in order to assess the impact of the parameters on the elimination of defects and finalizing the projected structure.

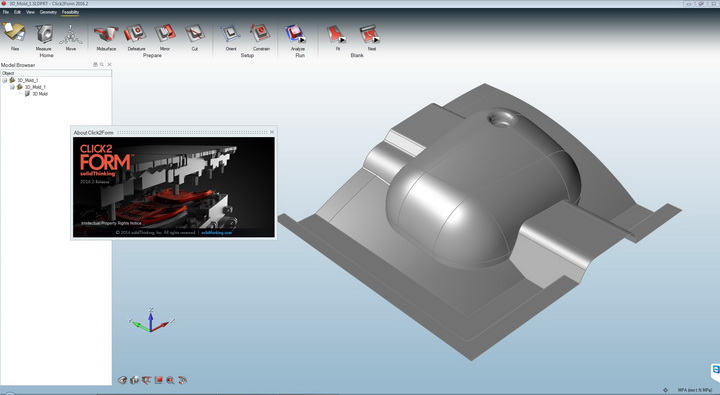

Altair Inspire Form Interface

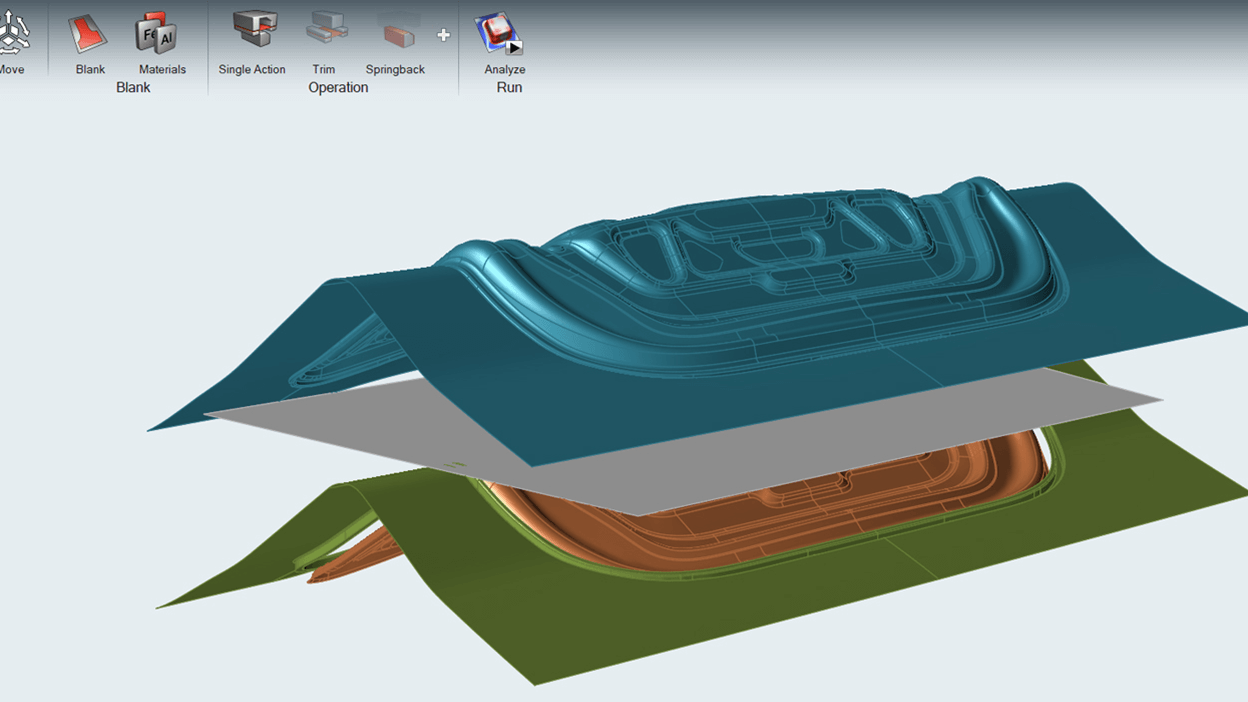

Acceleration of the design of the working surface of the stamp and production planning:

- Prediction of possible stamping defects in the process of designing the stamp surface, in order to correct them before the start of a detailed design analysis;

- Assistance to stamp designers in determining the working conditions of production, such as the downforce for the workpiece, the location of the forming rollers and the forces on them, before conducting a detailed design analysis.

An extensive set of geometric tools for product design and analysis:

Comprehensive tools for analyzing the technological characteristics of products:

- A group of tools for creating sketches;

- Solid-state modeling;

- Boolean operations;

- Geometry Simplification Tools;

- The possibility of highlighting the median surfaces.

Comprehensive tools for analyzing the technological characteristics of products:

- Verification of technological feasibility for conventional and template-welded parts;

- Technical feasibility check for single or double production processes;

- Built-in database of materials based on the SAE standard, with the possibility of organizing a user base, with the addition of your own materials.