e-Mobility

Delivering e-Mobility to the masses is not only a huge investment, but a significant operational undertaking. As OEMs, suppliers and emerging vehicle manufacturers invest billions to develop innovative electric vehicles, and optimize development and production processes, they are looking for a strategic partner to help realize their vision. Altair technologies are changing the way electric passenger, off-highway and autonomous vehicles are designed, enabling them to accelerate product development, enhance energy efficiency, and optimize integrated system performance.

Sustainable design solutions to meet next-gen vehicle demands.

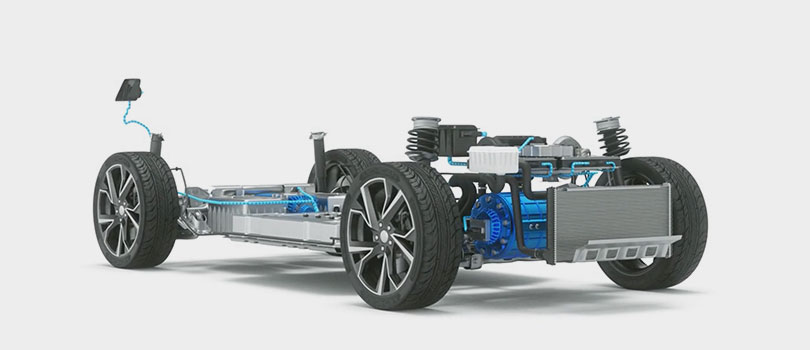

Integrated system-level, multi-disciplinary and multiphysics solutions offer designers the ability to understand and optimize the complex, connected architectures of today’s battery-electric vehicles (BEVs).

Scaling e-Mobility from niche to mass-market.

As OEMs begin to create BEV for their mainstream customers to address issues like range, drivetrain efficiency and charging times, design becomes an even more vital component of the development process. This requires fast exploration of higher system voltages, innovative cooling implementations and the ongoing race to reduce vehicle weight.

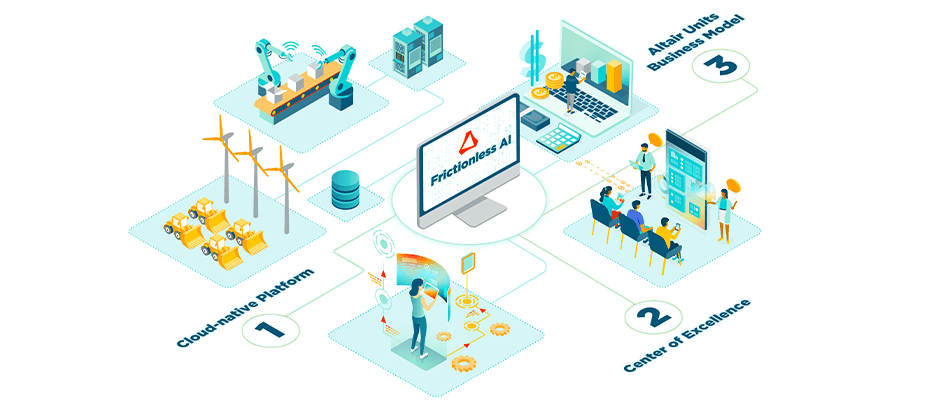

Bringing the power of cloud bursting to boost vehicle development programs.

On-demand, high-performance computing (HPC) presents the opportunity to securely scale simulation capabilities during peak demand, satisfying the need for detailed multi-disciplinary optimization studies on multiple programs to reduce development costs and risk.

Using data analytics to shape early vehicle decisions.

Early design exploration can be accelerated to identify the most promising concepts and a subset of critical performance criteria by applying statistical methods for dimensionality reduction of the huge number of design variables considered during a vehicle program.

Altair RapidMiner delivers breadth and depth across the analytics lifecycle.

Accelerate Product Development

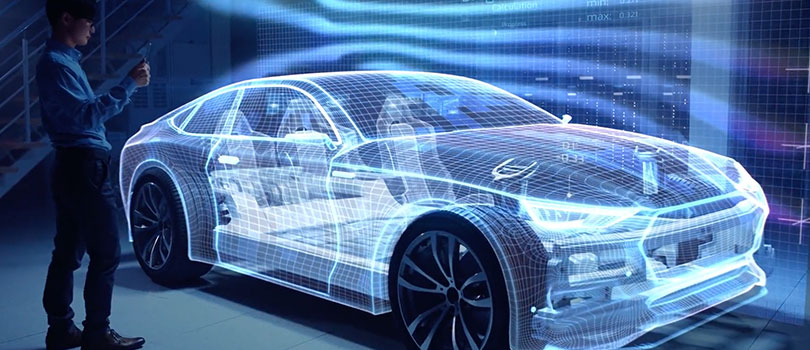

BEV product development: Aligning BEV development cycles with traditional powertrain vehicle program timelines requires changes to engineering team structures and toolsets. To address unique challenges, simulation-driven design processes help advance concepts to the design stage with fewer redesigns and physical prototypes. Altair® e-Motor Director™ is a single working environment where specialists can provide best-practice stored as solutions which users can drop and connect into more complex workflows, ready to be executed automatically.

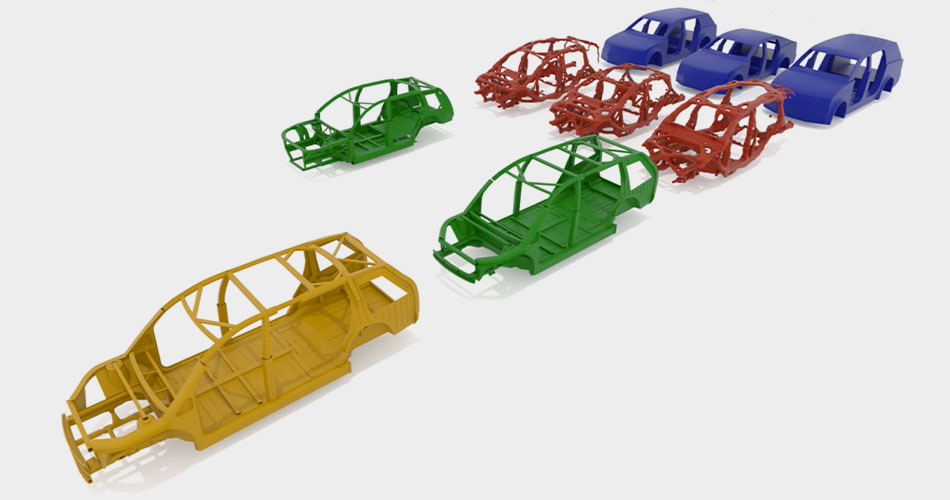

Lightweighting during pre-program for balanced design: Mass reduction is a key contributor to the battery range and e-propulsion performance. The Altair Concept 1-2-3 design process enables designers to confidently create and assess innovative next generation architectures by using simulation to inform vehicle architecture, manufacturing processes, material selection, and platform strategies.

Design exploration for informed e-motor selection: Use rapid design exploration and feasibility ranking during concept phase to inform optimal downstream e-propulsion decisions. Altair® FluxMotor® can be used to make performance comparisons to select the best e-motor topologies, considering constraints like efficiency, temperature, weight, compactness, and cost.

Enhance Energy Efficiency

Wide-ranging vehicle range: Lighter cars require less battery power for accelerating and maintaining speed, allowing a single charge to go further. Generative design enables engineers to remove material, while maintaining strength and stiffness properties required for safety and comfort. With less power required, the battery pack size and weight is reduced, one of the biggest contributors to an electric car’s weight.

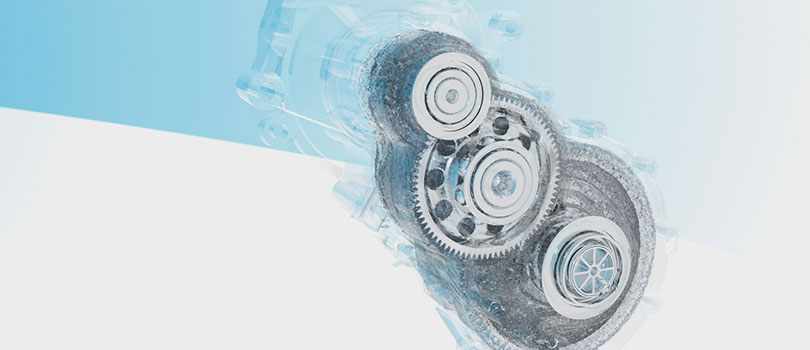

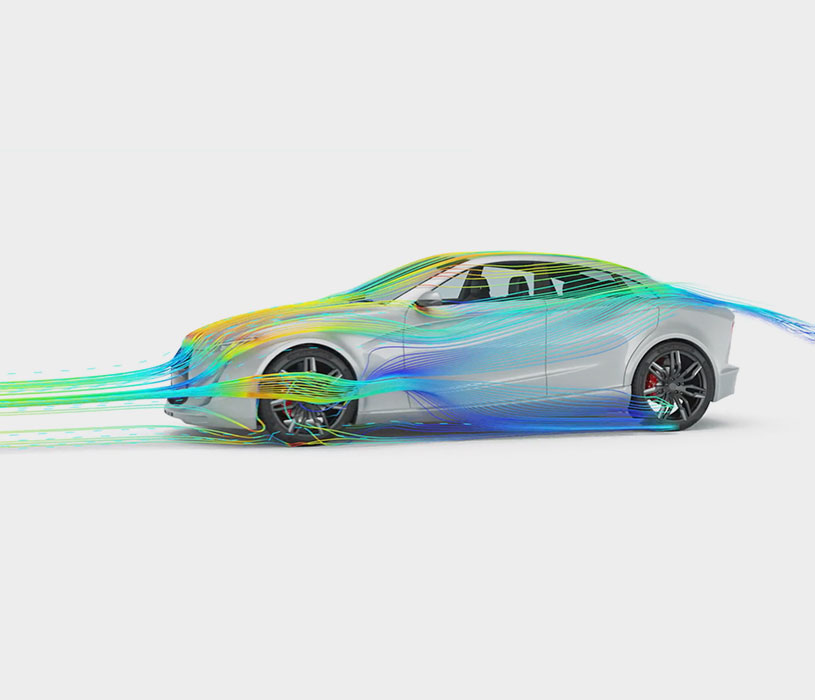

Detailed design for efficiency, cooling and noise: To balance performance, cost and weight requirements, designers can utilize multiphysics simulation to enhance the e-Mobility driving experience. Detailed e-motor electromagnetics with Altair® Flux® and magneto-thermal simulation with Altair CFD™ evaluates the convection and radiation contributing to efficiency losses. Altair® OptiStruct®offers insight into sound quality and passenger experience influenced by e-propulsion systems, as well as wind and road noise with Altair CFD.

e-Mobility challenges in crash and safety: The battery pack is critical in e-Mobility safety, and insights from the simulation of vehicle crash events, road debris impact and shocks need to align with the speed of your vehicle program. Altair’s investment in vehicle safety, in collaboration with leaders in vehicle battery research, now enables efficient and accurate analysis of mechanical failures that could lead to battery fires because of a short circuit.

Detailed design for efficiency, cooling and noise: To balance performance, cost and weight requirements, designers can utilize multiphysics simulation to enhance the e-Mobility driving experience. Detailed e-motor electromagnetics with Altair® Flux® and magneto-thermal simulation with Altair CFD™ evaluates the convection and radiation contributing to efficiency losses. Altair® OptiStruct®offers insight into sound quality and passenger experience influenced by e-propulsion systems, as well as wind and road noise with Altair CFD.

e-Mobility challenges in crash and safety: The battery pack is critical in e-Mobility safety, and insights from the simulation of vehicle crash events, road debris impact and shocks need to align with the speed of your vehicle program. Altair’s investment in vehicle safety, in collaboration with leaders in vehicle battery research, now enables efficient and accurate analysis of mechanical failures that could lead to battery fires because of a short circuit.

Designing the Future of e-Mobility

EV performance optimization: EV subsystems have considerable influence on surrounding systems, providing opportunities to optimize vehicle performance. Using a multi-disciplinary approach, designers can analyze and optimize key performance attributes across complex systems to find a balanced final design.

Drive and control integration: Altair’s model-based development solutions leverage simulation models to accelerate design delivery, while supporting different levels of mechatronic system complexity. Varying levels of model fidelity (from 0D to 3D) can be deployed in electric machine, power converter and control strategy design to match the vehicle development phase. 1D and 3D simulation studies can be coupled, sequentially or simultaneously to evaluate product performance through representative system models, all built to enhance design efficiency.

V2X, ADAS and autonomous vehicles: e-Mobility solutions must connect and interact with their surroundings without interfering with in-vehicle electrical systems (EMC/EMI). Altair® Feko® high-frequency electromagnetics software and wave propagation tools help vehicle designers perform virtual drive testing, and consider a full array of environmental obstacles using either Dedicated Short Range Communications (DSRC) or 5G wireless signals.

Drive and control integration: Altair’s model-based development solutions leverage simulation models to accelerate design delivery, while supporting different levels of mechatronic system complexity. Varying levels of model fidelity (from 0D to 3D) can be deployed in electric machine, power converter and control strategy design to match the vehicle development phase. 1D and 3D simulation studies can be coupled, sequentially or simultaneously to evaluate product performance through representative system models, all built to enhance design efficiency.

V2X, ADAS and autonomous vehicles: e-Mobility solutions must connect and interact with their surroundings without interfering with in-vehicle electrical systems (EMC/EMI). Altair® Feko® high-frequency electromagnetics software and wave propagation tools help vehicle designers perform virtual drive testing, and consider a full array of environmental obstacles using either Dedicated Short Range Communications (DSRC) or 5G wireless signals.