Altair Inspire Extrude is a new word in the technology of modeling the process of extrusion of metals and polymers; it is a software product of express modeling of extrusion of metals and polymers and is divided into two full–fledged modules: metal extrusion and polymer extrusion.

Altair Inspire Extrude™ Metal and Extrude™ Polymer are modeling environments designed to help manufacturers of metal and polymer extrusion products meet the ever–growing need for the production of complex profiles that must meet tight tolerances, have high-quality machined surfaces and have increased strength while reducing costs.

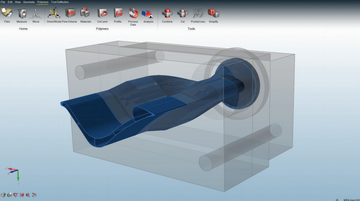

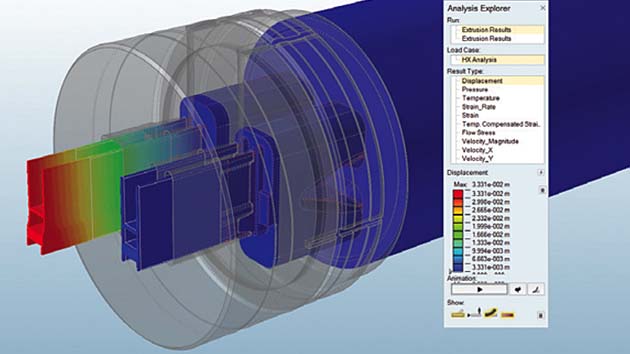

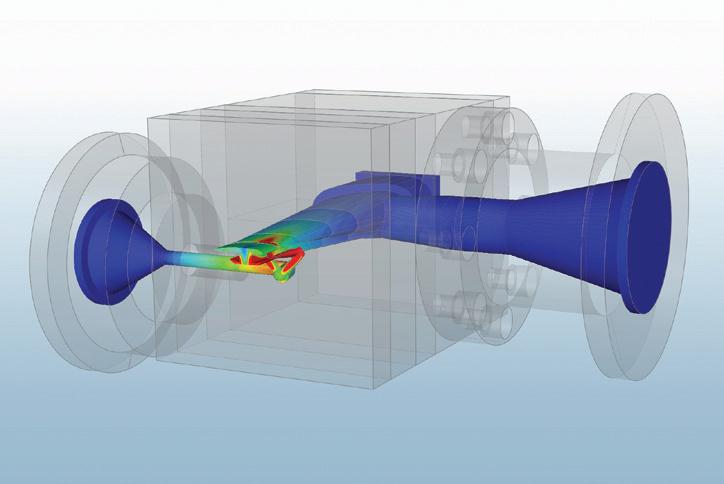

Altair Inspire Extrude Metal and Extrude Polymer are the creation of virtual models of presses in which users can see the melt flow and temperature inside the extrusion head during the extrusion process, assess the likelihood of material stagnation zones and junction lines and make the necessary changes to ensure a balanced flow, identifying and eliminating defects.

Altair Inspire Extrude Metal and Extrude Polymer are the creation of virtual models of presses in which users can see the melt flow and temperature inside the extrusion head during the extrusion process, assess the likelihood of material stagnation zones and junction lines and make the necessary changes to ensure a balanced flow, identifying and eliminating defects.

Key Advantages of Altair Inspire Extrude:

Altair Inspire Extrude™ Metal allows:

- Evaluate the profile deviation

- Evaluate the unevenness of the profile wall thickness

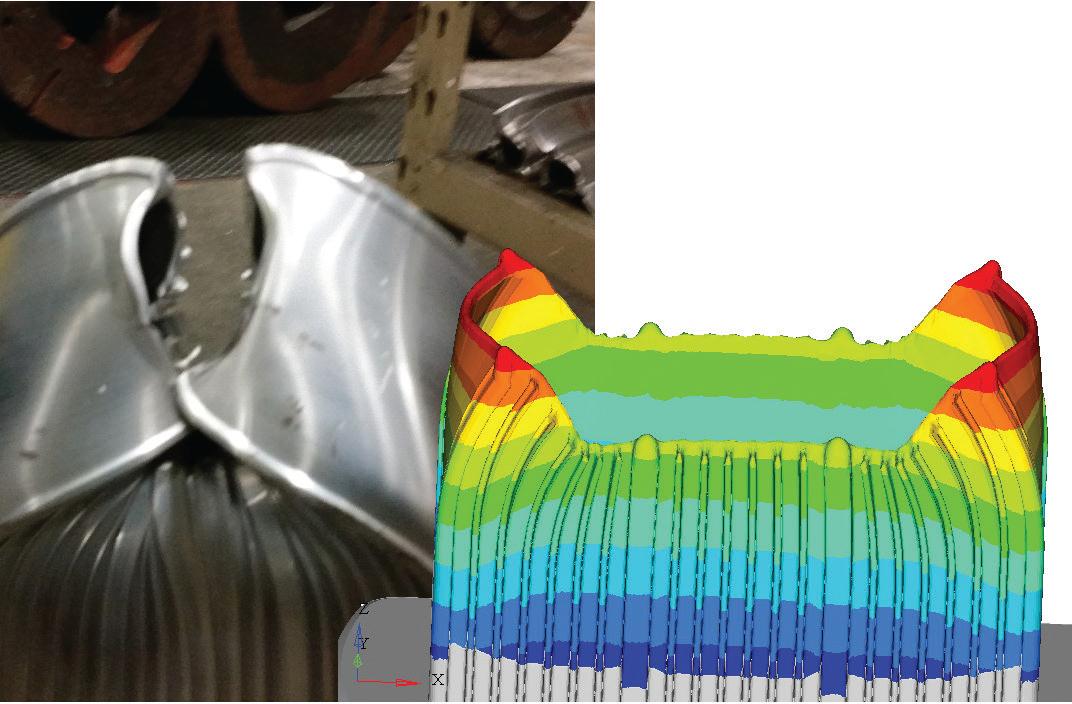

- Assess the presence of defect lines (pick-up lines) and junction lines

- Predict the presence of seams in hollow profiles

- Predict end defects

- Estimate grain size

- Optimize the length of the guide belt

- Evaluate the deplanation of the form

- Evaluate the wear of the mold and the presence of excess heat

- Improve the heat exchange of the structure

Altair Inspire Extrude™ Metal allows:

- Evaluate the profile deviation

- Evaluate the unevenness of the profile wall thickness

- Assess the presence of defect lines (pick-up lines) and junction lines

- Predict the presence of seams in hollow profiles

- Predict end defects

- Estimate grain size

- Optimize the length of the guide belt

- Evaluate the deplanation of the form

- Evaluate the wear of the mold and the presence of excess heat

- Improve the heat exchange of the structure

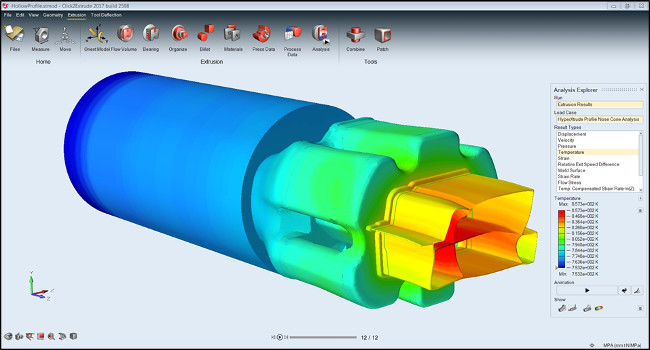

Altair Inspire Extrude™ Polymer allows:

- Evaluate the profile deviation

- Evaluate the longitudinal shrinkage of the extruded flow

- Simulate co-extrusion, including with metal inserts

- Simulate extrusion in spiral shapes

- Determine the deviation and deformation of the tool

- Evaluate the wear of the mold

- Evaluate the profile deviation

- Evaluate the longitudinal shrinkage of the extruded flow

- Simulate co-extrusion, including with metal inserts

- Simulate extrusion in spiral shapes

- Determine the deviation and deformation of the tool

- Evaluate the wear of the mold

Altair Inspire Extrude software does not require a separate preprocessor and allows you to import CAD geometry in just one click, check the integrity of the geometry and correct model defects, as well as, if necessary, simplify the solid-state 3D model.

Both Inspire Extrude Metal and Inspire Extrude Polymer allow you to quickly create a calculation model and tooling in a user-friendly “ribbon-styled” interface. The program can automatically generate a high-quality finite element grid to create a computational model. The Inspire Extrude database contains dozens of different metallic and non-metallic materials with a complete library of properties - aluminum, steels, magnesium alloys, titanium alloys, polymers. The user can also add their own material.

Altair Inspire Extrude operates under the universal Altair platform licensing system (solidThinking) Inspire, based on the placement of STU tokens required to launch any platform product on the customer's central server.

Both Inspire Extrude Metal and Inspire Extrude Polymer allow you to quickly create a calculation model and tooling in a user-friendly “ribbon-styled” interface. The program can automatically generate a high-quality finite element grid to create a computational model. The Inspire Extrude database contains dozens of different metallic and non-metallic materials with a complete library of properties - aluminum, steels, magnesium alloys, titanium alloys, polymers. The user can also add their own material.

Altair Inspire Extrude operates under the universal Altair platform licensing system (solidThinking) Inspire, based on the placement of STU tokens required to launch any platform product on the customer's central server.